Share to

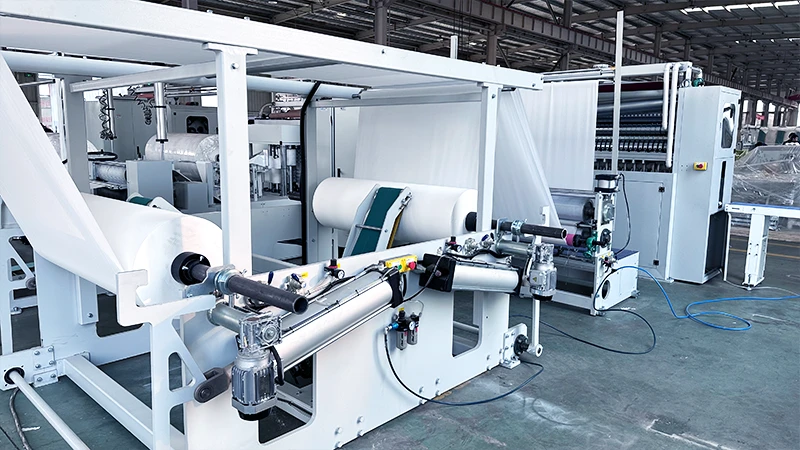

Paper packaging machine

Still deciding? Get samples first, Contact US !

View similar products

- Description

-

1.Advanced bus system improves performance and stability.

This equipment adopts the advanced EtherCAT bus system and abandons the traditional pulse system. This change brings significant advantages and greatly improves the system's anti-interference ability, enabling it to operate stably in complex and changeable industrial environments. At the same time, it effectively avoids the interference accumulation error that may occur during the servo movement process, ensures the high precision and reliability of the equipment, and provides a solid guarantee for the smooth progress of the production process.

2.Precision motion control system to achieve efficient collaborative operation.

Equipped with an advanced motion control system to precisely control 4 sets of servo motors. The system can make the coordination between the servo motors smoother and more seamless, and the servo motion process is stable and gentle, greatly improving the humanization of the operation. During use, operators can not only feel the simplicity of operation, but also experience the high accuracy of equipment positioning and the stability during operation, thereby improving production efficiency and product quality.

3.Absolute value encoder system ensures position memory and adjustment convenience.

The servo system adopts an advanced absolute value encoder system. This unique design allows the device to accurately memorize the position information of the motor even in the case of power failure. When the power is turned on again, the operator can easily adjust the equipment without recalibration or setting, which greatly saves time and improves production continuity and efficiency.

4.High-quality sensors ensure stable and accurate detection.

In the selection of photoelectric sensors, we insist on using well-known imported brand products. High-quality sensors provide reliable protection for the detection of equipment with their excellent performance and stable quality. Whether in high-speed operation or complex environment, they can accurately capture and feedback information to ensure the stability and accuracy of equipment detection, thereby effectively avoiding production problems that may be caused by detection errors.

5.Unique heating system to create perfect sealing effect.

The heating system adopts a unique and innovative constant temperature sealing control method. Through precise temperature control and uniform heat distribution, the smoothness and perfection of the sealing process can be guaranteed. Whether it is thin sheet material or thick packaging, it can achieve high-quality sealing effect, meet the packaging needs of different products, and improve the appearance quality and market competitiveness of products.

6.Intelligent tension adjustment system ensures stable tension of unwinding materials.

For tension adjustment, we use a control method that combines frequency converters with floating rollers. This advanced adjustment mechanism can accurately control the tension of unwinding materials in real time according to actual production conditions. It can not only effectively avoid problems such as material stretching and deformation caused by excessive or insufficient tension, but also ensure the stability and continuity of the entire production process and improve the qualified rate of products.

7.Selected standard parts to ensure reliable operation of equipment.

For standard parts of equipment, we use well-known domestic and foreign brand devices. These high-quality standard parts that have been strictly screened and tested have the characteristics of reliable quality and stable performance. They play a key role in the long-term operation of equipment, can effectively reduce the failure rate of equipment, reduce maintenance costs and downtime, and provide strong support for the production activities of enterprises.

8.Highly automated design improves production efficiency and flexibility.

The equipment has highly automated operation functions. It uses servo film lowering technology, the touch screen adjusts the length, and can automatically calculate and indicate the mechanical position. This intelligent design makes it faster and more convenient to change packaging specifications, greatly improving production efficiency, while also enhancing the adaptability and flexibility of the equipment to different product specifications, meeting the diverse production needs of enterprises.

9.Compact structure for easy connection to production lines. The design of the whole machine focuses on compact structure and small footprint. This feature enables the equipment to maximize its efficiency in a limited space and facilitates connection and integration with the production line. Whether it is a new production line or an upgrade of an existing production line, the equipment can be easily integrated into it, providing more convenience and possibilities for the production and layout of the enterprise.

Paper packaging machine

Still deciding? Get samples first, Contact US !

Products Category

Production base for household paper production

and processing equipment

Partners

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!